Importance Of Effective Load Cell Calibration

We create blogs to help our clients and visitors with difficulties related to Load cell calibration. The following blog will explain how to do load cell calibration and why you should do so.

Load cells must be accurate throughout their lifespan, whether they are used for periodic testing or continuous monitoring. Load cell Calibration guarantees that your load cells are accurate and functional according to established standards.

Load cell Calibration is the process of comparing a load cell or torque sensor to a known-accurate reference standard. The purpose of load cell calibration is to verify the instrument’s accuracy, traceability, and a direct relationship between a known applied force or torque, the reference standard, and the sensor’s output.

Why should I calibrate my load cell?

In order to use load cells effectively, you must first do a complete load cell calibration of your application. The purpose of calibration is to ensure that the sensors are working properly and that your application is reporting the correct values that are consistent with a calibration standard under specific conditions.

Load cells must be calibrated on a regular basis to maintain their accuracy. The best approach to remain on top of necessary maintenance is to stick to a regular maintenance schedule. The load cell is more susceptible to any type of disruption if it is not calibrated. Ensure to recalibrate after making repairs to the load cell.

For best results, the load cell (Test unit) should be exercised to full load three times before the calibration process. The master load cell should be used only up to 80% of the measuring range, which increases the fatigue life of the load cell.

The performance of measurement equipment is determined by calibration. You can measure securely, maintain compliance, and prevent the expenses of incorrect readings by performing routine equipment calibration and adjustment.

Faulty cables and instruments, particle collection and matter buildup, mechanical defects, improper installation, and the impact of electricity can all lead to inefficiency. To ensure the efficiency and accuracy of load cells, routine calibrations should be done.

Calibration of load cells on a regular basis can help to attain accuracies of 0.02 to 0.03% of full scale. Load cells must be calibrated to national standards or OIML / NIST Standards as part of product liability, safety, and compliance in a Quality Management System.

Why should I calibrate my load cell?

Examine whether the machine is providing accurate measurement output before calibrating load cells.

- When the system is unloaded or empty, the weight indicator should revert to zero.

- Throughout the full range and should fall in the error bandwidth of 0.02 to 0.03% of full scale.

- The weight indicator must give equal readings regardless of where the load is applied.

It is safe to assume that the load cells and transducers are operational if all of the criteria are met.

- Because of faulty wires and improper installation, load cells may generate misleading results.

- Before load cell calibration, Examine the electrical wires and cables.

- Dummy cells should be used in place of operational load cells until the construction and welding work is completed.

If you find that load cells are producing problems after running the preliminary tests, do the following tests: MECHANICAL INSPECTION:

Physical damage to the load cell should be checked. It cannot be repaired if it has been physically damaged, such as bent, stretched, or compressed from its original shape. On all metal surfaces, look for distortion or cracks. Both end surfaces of the flexure must be perpendicular to one other and parallel to each other. Ensure that all cables are checked over their whole length. A load cell can be shorted by nicked or abraded cables.

NO LOAD (ZERO BALANCE):

Residual tension in the sensing area is frequently the cause of shifts in the zero balance. Overloading the cell or repeating operation cycles will cause residual strains. Measure the output of the load cell using a multi voltmeter while there is no weight on the cell. It should be within 0.2 percent of the zero output signal given. The cell is damaged if the output is outside the zero balance tolerance range, but it may be repairable.

BRIDGE RESISTANCE

Measure the resistance between each input and output lead pair. Compare these readings to the load cell’s specifications. Failure of one or more elements, frequently as a result of electrical transients or lightning strikes, causes out-of-tolerance readings.

RESISTANCE TO GROUND

Measure the resistance between the load cell body and the leads with an ohmmeter after connecting all the input, output, sense, and ground leads together. A reading of at least 5,000 megaohms is required. Repeat the test without the ground wire if the load cell fails this step. The load cell will need to be repaired if it continues to fail. If it passes, it’s possible that the issue is with the load-cell cable. Short-circuiting (current flow) between the load cell’s electronics and the cell body is mainly caused by moisture penetration.

To load cell calibration, follow these steps:

- Place the scale on a stable platform and in a secure area to begin. Please select a place with the least amount of air currents and vibrations.

- Switch to calibration mode. From the drop-down menu, select the Set-Up option. Select Platform Setups as well as Span Calibration. After that, you’ll have to input a test weight.

- You must decide on a test value weight. This weight must stay within the scale constraint and be around half of the upper capacity.

- Make sure there are no things on the platform, and that the scale’s bottom is not in contact with anything. You should press the Enter key.

- After that, press the ‘Calibrate’ button.

- You’ll be instructed to place the test object on the scale. The item must be placed in the centre of the platform. Once the scale has stabilised, press enter. After the calibration process is done, the device will go to the platform menu.

You may rest assured that your equipment is in good working order if you follow these instructions.

Would you like to learn more about our scales or load cell calibration process?

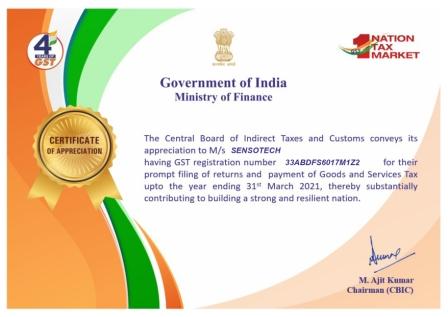

Sensomatic will provide a load cell calibration service for all types of load cells and load indicators.

Sensomatic specialised in delivering customized sensors design to suit a wide range of industrial applications. To know more about Sensomatic, please contact us on +91 98848 69600 or sales@sensotechindia.com.

For more information please visit: https://sensomaticloadcell.com/