Load cell for Aircraft Weighing System

The pilot must undertake a weight and balance check every time an aircraft weighing system or helicopter is readied for a flight. This method ensures that the Load cell for Aircraft Weighing System and helicopter fly safely within the manufacturer’s performance envelope. Most aircraft, regardless of size, require new weight and balance information on a frequent basis. Installation or removal of equipment after repairs and alterations, or as part of the aircraft or operator’s maintenance schedule, requires the use of the most correct weight and balance data.

For aircraft applications, load cells are a perfect choice A load cell for aircraft weighing systems is a sensor capable of measuring or detecting push and pull forces. These sensors are usually mounted parallel to the force being applied to an assembly or system.

Aircraft weighing systems that employ platform scales with load cells are indispensable for maintaining safety, optimizing performance, and conducting various aerospace activities. These measurements assist in ensuring that an aircraft operates within its specified weight limits and maintains proper weight distribution, which is critical for flight safety and efficiency. Platform scales with load cells for aircraft weighing systems are used to weigh aircraft. Typically, the plane is pushed forward until all of the wheels are on the platforms. The overall weight is then calculated as the sum of each platform’s readings. Weigh distribution is calculated using distances and differences between platform readings. The Control Indicator, which measures load data from Load cells, is the most important aspect of the system. Each weighing platform is managed separately and is shown at the appropriate display before displaying the total These force measurements can be useful for a variety of aerospace applications, including research and development, in-flight testing, ground testing, and onboard aircraft measurements.

In Aerospace Applicationsapplications Of Loadcells In Aerospace

The Advantages Of Using Load Cells

Why we are rated as the best Load cell manufacturers in

India for Aerospace Applications?

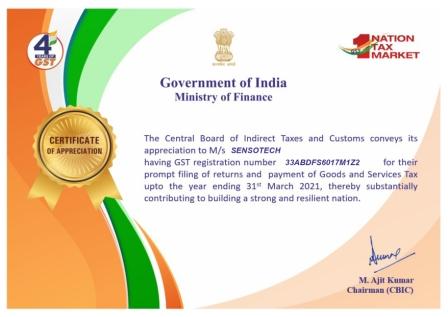

Sensomatic manufactures aircraft weighing system, aircraft scales, helicopter scales, and platform scales for small aircraft up to large jets. For your needs, the company manufactures the proper size and weight scale. We manufacture load cell for aircraft weighing system that can be integrated into an aircraft weighing system to both accurately weigh the aircraft and provide its center of gravity. Our load cells are all built to the highest quality standards, making them ideal for sectors that place a high value on safety and quality. For more than a decade, Sensotech has been supplying weighing equipment to the aircraft industry. Sensomatic load cells now feature revolutionary radial top technology, which improves accuracy.

Some of the applications for airplane weighing load cells are listed below:

- Component Fatigue Tests

- Measurement Of Shock And Vibration

- Testing for impact

- Tests Of Structural Function

- Testing Of Aerodynamics

- Pedal Force Assessment

- Aircraft Weighing System