Load Cell Suppliers in Nellore

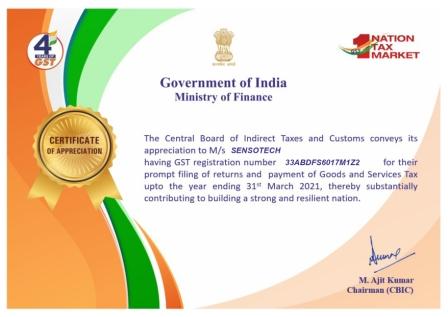

Sensomatic is one of the trusted load cell manufacturers and suppliers in Nellore, with a fairly extensive line of supplies in load cells. Sensotech is promoted by sensomatic load cell which provides a list of products such as transducers, load cells, and indicators at affordable rates.The market of Nellore is profoundly a vast and serious one.Our clients are satisfied with our load cell’s quality, accuracy, and durability.

In Nellore, if you are in search of load cell manufacturers and suppliers, Sensomatic is a reliable option. They provide high-quality load cells that accurately measure force or weight and can be used in various industries such as agriculture, healthcare, automotive, and more.

OUR LIST OF PRODUCTS

We have wide collections of load cells and customized products matching client requirements and applications. We are a top supplier of load cells, weighing modules, indicators, accessories, instrumentation and various custom products in and around Nellore. Value is tangible, intangible, institutional and personal; and we deliver all of these–in a mixture tailored to our specific client–to build a trusted partnership, hence we have a vast clients all over Nellore. Here are some of our top-selling load cell products.

- Aluminum load cells

- Single-point load cells

- Single-ended shear beam load cells

- S-type load cells

- Universal load cells

- Double-ended shear beam load cells

- Rope tension load cells

- Compression load cells

- Rocker columns

- Beam deflection sensor

- High-speed load sensor

- Shear pin load cell

- Motor bed sensor

- Crane load cell

- Elevator sensor

- Disc sensor

Load Cell Suppliers in Nellore ,Andhra Pradesh

Sensomatic is a supplier of load cells located in Nellore, Andhra Pradesh. They offer a wide range of load cells for various applications, including compression load cells, tension load cells, and more. Whether you’re in need of load cells for industrial or commercial use, Sensomatic has the expertise and products to meet your needs.

WHY CHOOSE SENSOMATIC LOADCELLS

As one of the great load cell suppliers in Nellore, Andra Pradesh there are numerous motivations to which we owe our effective status. One of the key things that have given our organization the greatest motivation is our assurance to keep the quality improving with time.

-

- Our load cells are prepared to perform inside a wide temperature range.

- Our load cells are intended to have variable limits that make them fit various tasks.

- As a provider, we make load cells that have applications in various ventures.

- Sensomatic is additionally a noticeable load cell exporter in India providing its customized transducers to countries outside India.

LOADCELL USAGES

Load cells represent one of the most precise technologies and are used within closed-loop regulation

- Load cells detect the web tension and send an input signal to the control panel.

- The Control panel compares the web tension detected with the ‘set point’ and send the input to the brake (or motor)

- Brake (or motor) – adjust the torque (or rpm if a motor) in order to obtain the web tension required.

Load cells are applied on rollers to precisely detect the tension of a web. There are various guiding types used for measurements,

1) EDGE GUIDING

Sensors are frequently used to monitor and control webs by measuring the web as it travels on the line. Like many industrial sensing applications, web and edge guiding applications often involve targets that are traditionally challenging for sensors to detect, including clear, reflective, and extremely dark targets.

In addition to the above, the high-speed operation of web-guiding equipment can challenge a sensor’s ability to detect and measure the material reliably. The most popular type of web position control includes achieving the desired edge alignment of the film at various stages of the process.

2) CHASER GUIDING

One another type of web position control includes chasing one or two webs to a reference web to achieve the desired edge alignment of multiple layers. It is very critical and important in the modern era to produce minimum wastage and accurate laminates. This can be done by either mechanically or electronically slaving two or more sensors. This directly results in minimum trim waste at higher accuracy and production. This setup is useful for the Lamination Machine process.

3) CENTER GUIDING

Center guiding applications may involve either fixed or moving sensor systems. The Web Guide System keeps the center line of the web in an exact position. In the case of the Moving sensor center guiding the sensors continuously reposition themselves automatically to detect both web edges and maintain the center line of the web in an exact position irrespective of any width variation. Our products are manufactured and designed using high-quality materials and cutting-edge technology for the better development of our products.

4) LINE GUIDING

This system uses a printed line, continuous patch, or any pattern on the web. Pneumo-Hydraulic Web Guiding System is used for any winding & unwinding application for guiding the web to reduce the wastage of the material & to get high production output with minimum manpower. The system maintains the chosen mark in an exact lateral position irrespective of the web edge position. This system is widely used in slitting machines.